Custom Brackets, Channels, Enclosures, Flanges & Much More

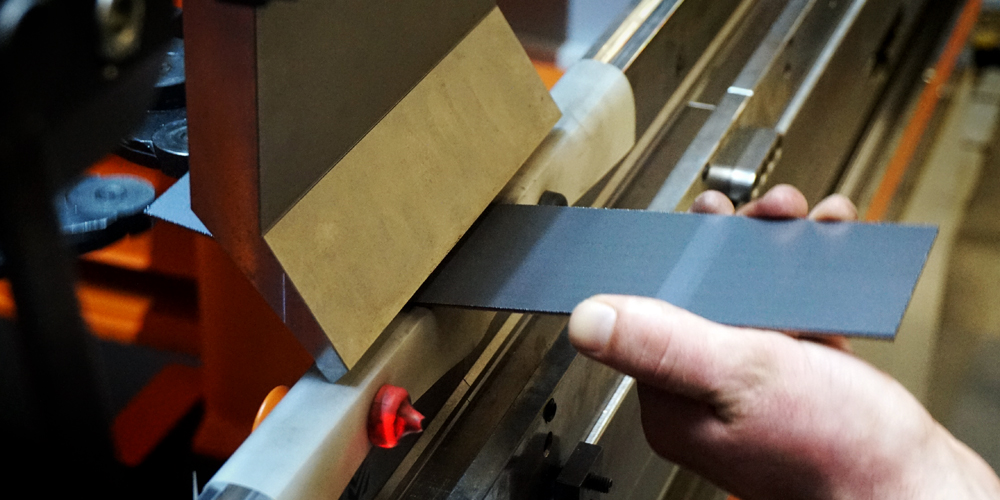

Our CNC press brake operators have the metal forming and metal fabrication experience required to manufacture the custom parts you need for your subassemblies. CNC metal forming allows for setups with greater accuracy, repeatability, and productivity. This means it takes our skilled staff less time to create high quality metal formed parts for you. That saves your company money.

From simple 90-degree bends to more complex sequences that include multiple bends and acute angles, we can manufacture your brackets, channels, enclosures, panels, flanges, cases, and much more. Terrene, Inc. can metal form to your precise requirements the following materials:

- Aluminum to 3/8” maximum thickness

- Mild steel to 3/8” maximum thickness

- Stainless steel to 1/4” maximum thickness

Our CNC press brake can make 100” maximum length bends, depending on material thickness and bend angles. Contact us with the specifications of your project for the exact details.

Other metal fabrication services we offer include:

- Laser cutting and laser etching

- Countersinking, hole tapping, and drilling

- Bead blasting

- Stroke sanding

- Pem® Nut installing

Industries we fabricate parts for include medical, engineering, lighting, electronics, aerospace, agriculture, architecture, and many others. Whether you need a quick prototype order fulfilled or a full production run of parts, Terrene, Inc. is your metal forming and metal fabrication vendor in the Greater Seattle area and across the nation. Contact us today.

Available Materials

-

Laser Cut And Metal Formed 3/16" Mild Steel Spring Perches

-

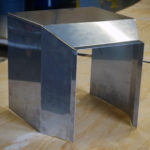

Laser Cut And Metal Formed 1/4" Mild Steel Parts

-

Laser Cut And Metal Formed 1/4" Mild Steel Bracket

-

Laser Cut And Metal Formed 16 Gauge Mild Steel Signs

-

Laser Cut And Metal Formed 16 Gauge Mild Steel Bracket

-

Laser Cut And Metal Formed 18 Gauge Mild Steel Parts

-

Laser Cut And Metal Formed 20 Gauge Mild Steel Candle Holder

-

Laser Cut 22 Gauge Steel Formed And Plated Part

-

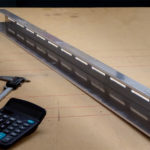

Laser Cut And Metal Formed 11 Gauge Stainless Steel C-Channels

-

Laser Cut And Metal Formed 11 Gauge Stainless Steel Fixture With Tapped Holes

-

Laser Cut And Metal Formed 14 Gauge Stainless Steel Bracket With Countersink Holes

-

Laser Cut, StayMark® Laser Marked, And Metal Formed 16 Gauge Stainless Steel Awards With #4 Finish

-

Laser Cut, Bead Blasted, StayMark® Laser Marked, And Metal Formed 16 Gauge Stainless Steel Table Tent With QR Code

-

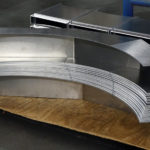

Laser Cut And Metal Formed 18 Gauge Stainless Steel Hopper Cover

-

Laser Cut And Metal Formed 18 Gauge Stainless Steel Card Holders

-

Laser Cut And Metal Formed 16 Gauge Galvanized Steel Brackets

-

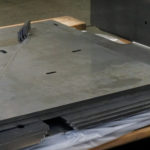

Laser Cut And Metal Formed Galvanized Plate

-

Laser Cut And Metal Formed 1/4" Aluminum Bracket

-

Laser Cut And Metal Formed 1/8" Aluminum Shelves

-

Laser Cut And Metal Formed 1/8" Aluminum Parts

-

Laser Cut And Metal Formed .100" And .080" Aluminum Parts

-

Laser Cut And Metal Formed .080" Aluminum Parts

-

Laser Cut And Metal Formed .080" Aluminum Parts With Countersink Holes

-

Laser Cut And Metal Formed .063" 6061 Aluminum Parts

-

Laser Cut And Metal Formed .063" Aluminum Part

-

Laser Cut And Metal Formed 14 Gauge Mild Steel And .100" Aluminum Subassembly

-

Laser Cut And Metal Formed Aluminum And Mild Steel Parts With PEM® Nuts Installed

-

Laser Cut And Metal Formed .063" Aluminum Brackets With PEM® Nuts Installed

-

Laser Cut And Metal Formed 1/16" 5052 Aluminum Brackets With PEM® Nuts Installed

-

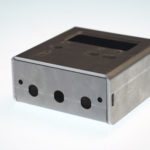

Laser Cut And Metal Formed .050" 5052 Aluminum Chassis With PEM® Nuts Installed

-

Laser Cut And Metal Formed 14 Gauge Mild Steel Brackets With PEM® Nuts Installed